Product Description

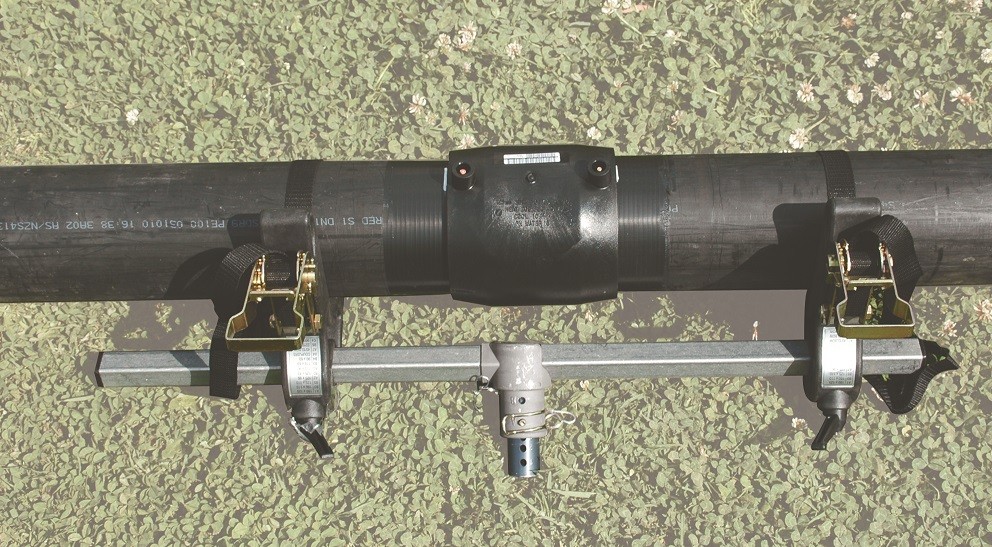

Acu-Tech supplies a range of Poly Welding Clamps, used when welding with electrofusion fittings, in order to align both ends of the pipe during scraping, heating, welding & cooling. Welding clamps are also known as alignment clamps, and are different to re-rounding clamps, which are used to ensure the weld does not fail because the pipe is an oval shape.

The alignment clamp is essential, even for smaller size pipe, to keep the pipe aligned while the electrofusion welding process is completed. It restrains the pipe from pulling out of the fitting or welder, and ensures the weld pressure is not reduced, because the pipe is being pulled from the end. Stress, misalignment or lack of pressure can result in weld failure in both butt welding and electrofusion welding. PIPA industry recommendations state: “The effectiveness of EF jointing depends on attention to preparation of the jointing surfaces and the geometry of the assembly, in particular the removal of the oxidised surface of the pipe over the socket depth or saddle mounting area, ensuring the jointing surfaces are clean and free from contamination, and the assembly and clamping instructions are correctly followed.” As the completed electrofusion joint should be left in clamps for cooling, it is ideal to own two identical sized clamps, to leave one clamp on the previous weld while it cools, and use the second clamp to prepare the next weld in advance. Welding alignment clamps are also known as electrofusion pipe alignment clamps.

Small electrofusion welding clamps are available from 20 mm to 63 mm capacity, stainless steel welding clamps are available from 20 mm to 63 mm pipe capacity, and larger welding clamps that can hold up to 710 mm poly pipe.

Butt welding clamp inserts are also available. These clamps come with the butt welding equipment when it is purchased, but if your welding clamp has been damaged, replacement clamps are available from Acu-Tech. Butt welder clamps hold the poly pipe in position when scraping, heating, welding & cooling the pipe.

For re-rounding clamps, see this link.

Need more info? Call us on

- Perth (08) 9238 8000

- Kalgoorlie (08) 9021 5075

- Melbourne (03) 9001 0029

- Brisbane (07) 3161 7647