Acu-Tech Piping Systems proudly offers a comprehensive selection of top-tier PE Poly Pressure Pipe Products, designed for versatility and high-performance excellence across an array of applications.

The remarkable flexibility and adaptability of PE Polyethylene pressure pipes make them indispensable in various industries. From mining and plumbing & drainage to infrastructure projects, industrial process plants, HVAC systems, irrigation & rural farming, as well as communications and power conduits, polyethylene pipe systems continue to demonstrate their value and reliability.

Discover the unmatched benefits of our PE Polyethylene Pressure Pipe Products today!

What is Polyethylene Pipe?

Polyethylene Pipe (PE), Polyethylene pressure pipe or poly pressure pipe as it is commonly known, is a commonly used polyethylene piping system for fluids and gasses throughout Australia.

Polyethylene’s toughness, immunity from corrosion, excellent resistance to chemicals and low weight have contributed to its continued appeal for use in situations where cost-effective and reliable piping systems are required.

Made from PE100 polyethylene material, Acu-Tech manufactures HDPE pressure pipes designed specifically for the following systems:

- Acu-Water (drinking water pipeline)

- Acu-Fire (fire main pipeline)

- Acu-Gas (gas pipeline)

- Acu-Therm (above ground pipeline)

- Acu-Drain (wastewater pipeline)

- Acu-Power (electrical conduit)

- Acu-Rural (imperial pipe for rural areas)

- Acu-Black (UV-resistant PE100 pipeline)

- Acu-Comms (communications conduit)

- Recycle-Tech (recycled water pipeline)

- Acu-Sewer (sewer pipeline)

- Acu-Fab (poly fabrication services)

- Acu-Subduct (conduit inner subduct)

- Acu-Air (blue jacket compressed air pipe)

Polyethylene Pressure Pipe HD-PE100

Acu-Tech’s HD-PE100 pipe comes in 20 mm to 800 mm in lengths and coils.

Clients have the option of striping or full coating for system-specific colour coding.

Backed with experience in working with Australia’s industrial, mining, utilities and plumbing sectors, our products and services are developed purposely to provide each sector with best-fitting solutions.

PE pipe fittings are available from Acu-Tech Piping Systems, a leading pipe manufacturing company in Perth, W.A.

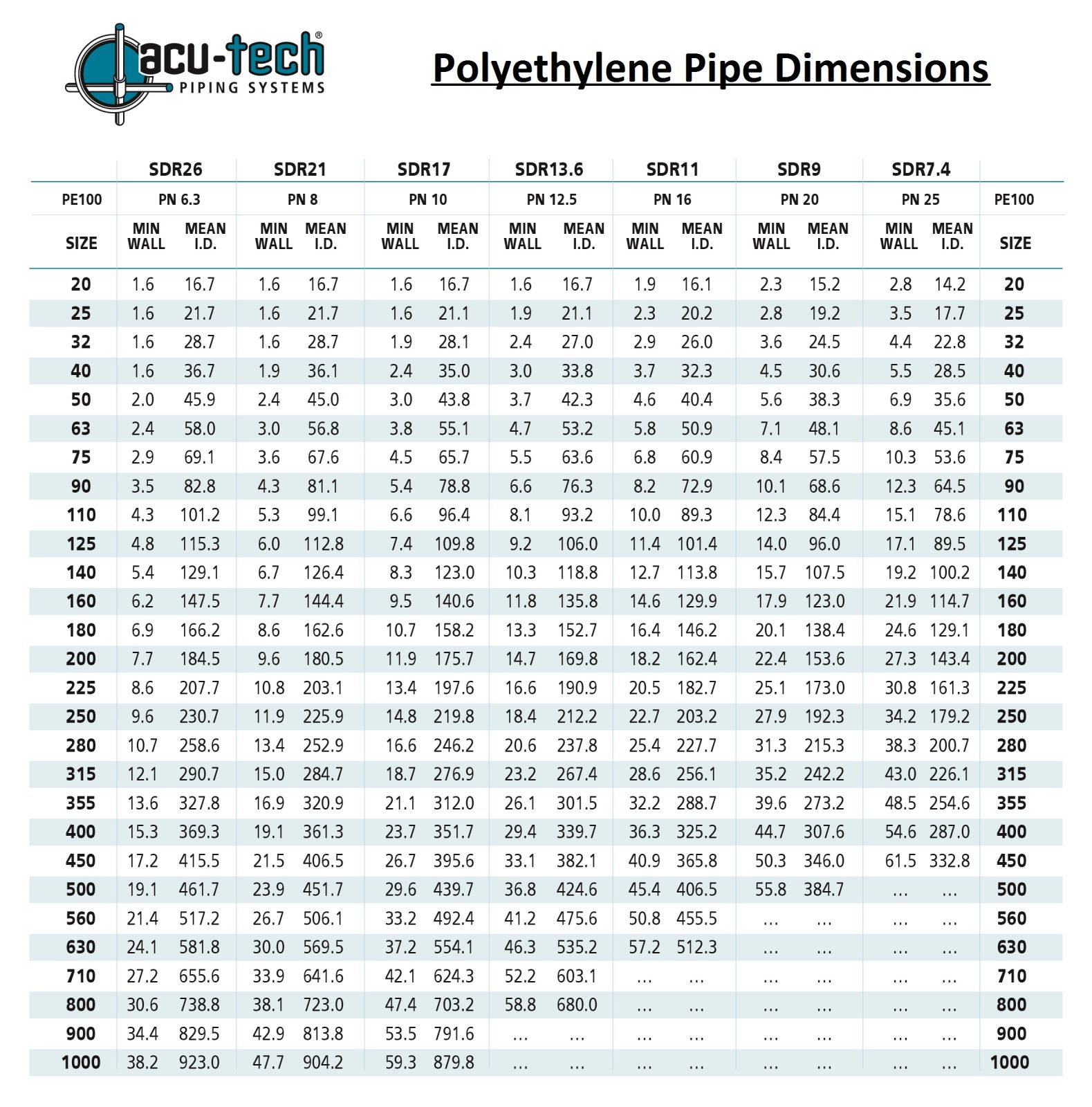

Custom PE pressure pipe can be made to order, including co-extruded HDPE pipe, custom SDR or PN rating poly pipe, and custom PE pipe lengths – see the pipe size chart below.

Acu-Tech‘s large diameter coiled HDPE pipe is strapped in layers, so the poly pipe coil does not dangerously unwind, as some vinidex pipes or iplex pipes are prone to do.

HDPE poly pressure pipe can be joined by a variety of methods, including electrofusion fittings, compression fittings, butt weld/short spigot fittings, HDPE transition fittings and BSP threaded adaptor fittings.

Polyethylene (PE Pipe) sizes / dimensions are as follows:

Polyethylene Pipe (PE) Dimensions DN20 to DN110

| DN20-110 | SIZE: | 20 | 25 | 32 | 40 | 50 | 63 | 75 | 90 | 110 |

|---|---|---|---|---|---|---|---|---|---|---|

| SDR 26 (PN 6.3) | MIN WALL | 1.6 | 1.6 | 1.6 | 1.6 | 2.0 | 2.4 | 2.9 | 3.5 | 4.3 |

| MEAN I.D. | 16.7 | 21.7 | 28.7 | 36.7 | 45.9 | 58 | 69.1 | 82.8 | 101.2 | |

| SDR 21 (PN 8) | MIN WALL | 1.6 | 1.6 | 1.6 | 1.9 | 2.4 | 3.0 | 3.6 | 4.3 | 5.3 |

| MEAN I.D. | 16.7 | 21.7 | 28.7 | 36.1 | 45.0 | 56.8 | 67.6 | 81.1 | 99.1 | |

| SDR 17 (PN 10) | MIN WALL | 1.6 | 1.6 | 1.9 | 2.4 | 3.0 | 3.8 | 4.5 | 5.4 | 6.6 |

| MEAN I.D. | 16.7 | 21.1 | 28.1 | 35.0 | 43.8 | 55.1 | 65.7 | 78.8 | 96.4 | |

| SDR13.6 (PN12.6) | MIN WALL | 1.6 | 1.9 | 2.4 | 3.0 | 3.7 | 4.7 | 5.5 | 6.6 | 8.1 |

| MEAN I.D. | 16.7 | 21.1 | 27.0 | 33.8 | 42.3 | 53.2 | 63.6 | 76.3 | 93.2 | |

| SDR 11 (PN 16) | MIN WALL | 1.9 | 2.3 | 2.9 | 3.7 | 4.6 | 5.8 | 6.8 | 8.2 | 10.0 |

| MEAN I.D. | 16.1 | 20.2 | 26.0 | 32.3 | 40.4 | 50.9 | 60.9 | 72.9 | 89.3 | |

| SDR 9 (PN 20) | MIN WALL | 2.3 | 2.8 | 3.6 | 4.5 | 5.6 | 7.1 | 8.4 | 10.1 | 12.3 |

| MEAN I.D. | 15.2 | 19.2 | 24.5 | 30.6 | 38.3 | 48.1 | 57.5 | 68.6 | 84.4 | |

| SDR 7.4 (PN 25) | MIN WALL | 2.8 | 3.5 | 4.4 | 5.5 | 6.9 | 8.6 | 10.3 | 12.3 | 15.1 |

| MEAN I.D. | 14.2 | 17.7 | 22.8 | 28.5 | 35.6 | 45.1 | 53.6 | 64.5 | 78.6 | |

| PEpipeSDRandPN | PipeDIAMETER | 20 | 25 | 32 | 40 | 50 | 63 | 75 | 90 | 110 |

Polyethylene Pipe (PE) DN125 to DN315

| DN125-315 | SIZE: | 125 | 140 | 160 | 180 | 200 | 225 | 250 | 280 | 315 |

|---|---|---|---|---|---|---|---|---|---|---|

| SDR 26 (PN 6.3) | MIN WALL | 4.8 | 5.4 | 6.2 | 6.9 | 7.7 | 8.6 | 9.6 | 10.7 | 12.1 |

| MEAN I.D. | 115.3 | 129.1 | 147.5 | 166.2 | 184.5 | 207.7 | 230.7 | 258.6 | 290.7 | |

| SDR 21 (PN 8) | MIN WALL | 6.0 | 6.7 | 7.7 | 8.6 | 9.6 | 10.8 | 11.9 | 13.4 | 15.0 |

| MEAN I.D. | 112.8 | 126.4 | 144.4 | 162.6 | 180.5 | 203.1 | 225.9 | 252.9 | 284.7 | |

| SDR 17 (PN 10) | MIN WALL | 7.4 | 8.3 | 9.5 | 10.7 | 11.9 | 13.4 | 14.8 | 16.6 | 18.7 |

| MEAN I.D. | 109.8 | 123.0 | 140.6 | 158.2 | 175.7 | 197.6 | 219.8 | 246.2 | 276.9 | |

| SDR 13.6 (PN 12.6) | MIN WALL | 9.2 | 10.3 | 11.8 | 13.3 | 14.7 | 16.6 | 18.4 | 20.6 | 23.2 |

| MEAN I.D. | 106.0 | 118.8 | 135.8 | 152.7 | 169.8 | 190.9 | 212.2 | 237.8 | 267.4 | |

| SDR 11 (PN 16) | MIN WALL | 11.4 | 12.7 | 14.6 | 16.4 | 18.2 | 20.5 | 22.7 | 25.4 | 28.6 |

| MEAN I.D. | 101.4 | 113.8 | 129.9 | 146.2 | 162.4 | 182.7 | 203.2 | 227.7 | 256.1 | |

| SDR 9 (PN 20) | MIN WALL | 14.0 | 15.7 | 17.9 | 20.1 | 22.4 | 25.1 | 27.9 | 31.3 | 35.2 |

| MEAN I.D. | 96.0 | 107.5 | 123.0 | 138.4 | 153.6 | 173.0 | 192.3 | 215.3 | 242.2 | |

| SDR 7.4 (PN 25) | MIN WALL | 17.1 | 19.2 | 21.9 | 24.6 | 27.3 | 30.8 | 34.2 | 38.3 | 43.0 |

| MEAN I.D. | 89.5 | 100.2 | 114.7 | 129.1 | 143.4 | 161.3 | 179.2 | 200.7 | 226.1 | |

| PEpipeSDRandPN | PipeDIAMETER | 125 | 140 | 160 | 180 | 200 | 225 | 250 | 280 | 315 |

Polyethylene Pipe (PE) DN355 to DN900

| DN355-900 | SIZE: | 355 | 400 | 450 | 500 | 560 | 630 | 710 | 800 | 900 |

|---|---|---|---|---|---|---|---|---|---|---|

| SDR 26 (PN 6.3) | MIN WALL | 13.6 | 15.3 | 17.2 | 19.1 | 21.4 | 24.1 | 27.2 | 30.6 | 34.4 |

| MEAN I.D. | 327.8 | 369.3 | 415.5 | 461.7 | 517.2 | 581.8 | 655.6 | 738.8 | 829.5 | |

| SDR 21 (PN 8) | MIN WALL | 16.9 | 19.1 | 21.5 | 23.9 | 26.7 | 30.0 | 33.9 | 38.1 | 42.9 |

| MEAN I.D. | 320.9 | 361.3 | 406.5 | 451.7 | 506.1 | 569.5 | 641.6 | 723.0 | 813.8 | |

| SDR 17 (PN 10) | MIN WALL | 21.1 | 23.7 | 26.7 | 29.6 | 33.2 | 37.2 | 42.1 | 47.4 | 53.5 |

| MEAN I.D. | 312.0 | 351.7 | 395.6 | 439.7 | 492.4 | 554.1 | 624.3 | 703.2 | 791.6 | |

| SDR 13.6 (PN 12.6) | MIN WALL | 26.1 | 29.4 | 33.1 | 36.8 | 41.2 | 46.3 | 52.2 | 58.8 | - |

| MEAN I.D. | 301.5 | 339.7 | 382.1 | 424.6 | 475.6 | 535.2 | 603.1 | 680.0 | - | |

| SDR 11 (PN 16) | MIN WALL | 32.2 | 36.3 | 40.9 | 45.4 | 50.8 | 57.2 | - | - | - |

| MEAN I.D. | 288.7 | 325.2 | 365.8 | 406.5 | 455.5 | 512.3 | - | - | - | |

| SDR 9 (PN 20) | MIN WALL | 39.6 | 44.7 | 50.3 | 55.8 | - | - | - | - | - |

| MEAN I.D. | 273.2 | 307.6 | 346.0 | 384.7 | - | - | - | - | - | |

| SDR 7.4 (PN 25) | MIN WALL | 48.5 | 54.6 | 61.5 | - | - | - | - | - | - |

| MEAN I.D. | 254.6 | 287.0 | 332.8 | - | - | - | - | - | - | |

| PEpipeSDRandPN | PipeDIAMETER | 355 | 400 | 450 | 500 | 560 | 630 | 710 | 800 | 900 |

The Acu-Tech Difference

- Specialist Poly Pipe Manufacturing in WA

- Quality Assurance- Poly Pipe WA

Our poly pressure pipes are manufactured in our state-of-the-art 38,500m2 facilities.

We have advanced CNC-controlled extruders allowing us to produce all diameters of HDPE pipes between 20 mm and 800 mm, both coiled and straight, here in Western Australia.

We also have a HDPE fabrication factory responsible for producing PE pressure pipe fittings, including bends, tees, spools and components to client specifications.

Our production process complies with stringent local and international standards. We adhere to the ISO 9001 and ISO/TS 29001 quality management systems backed with certifications.

Our HDPE pipes, electrofusion and spigot fittings are also WaterMark certified to AS/NZS 4130 and AS/NZS 4129, respectively.