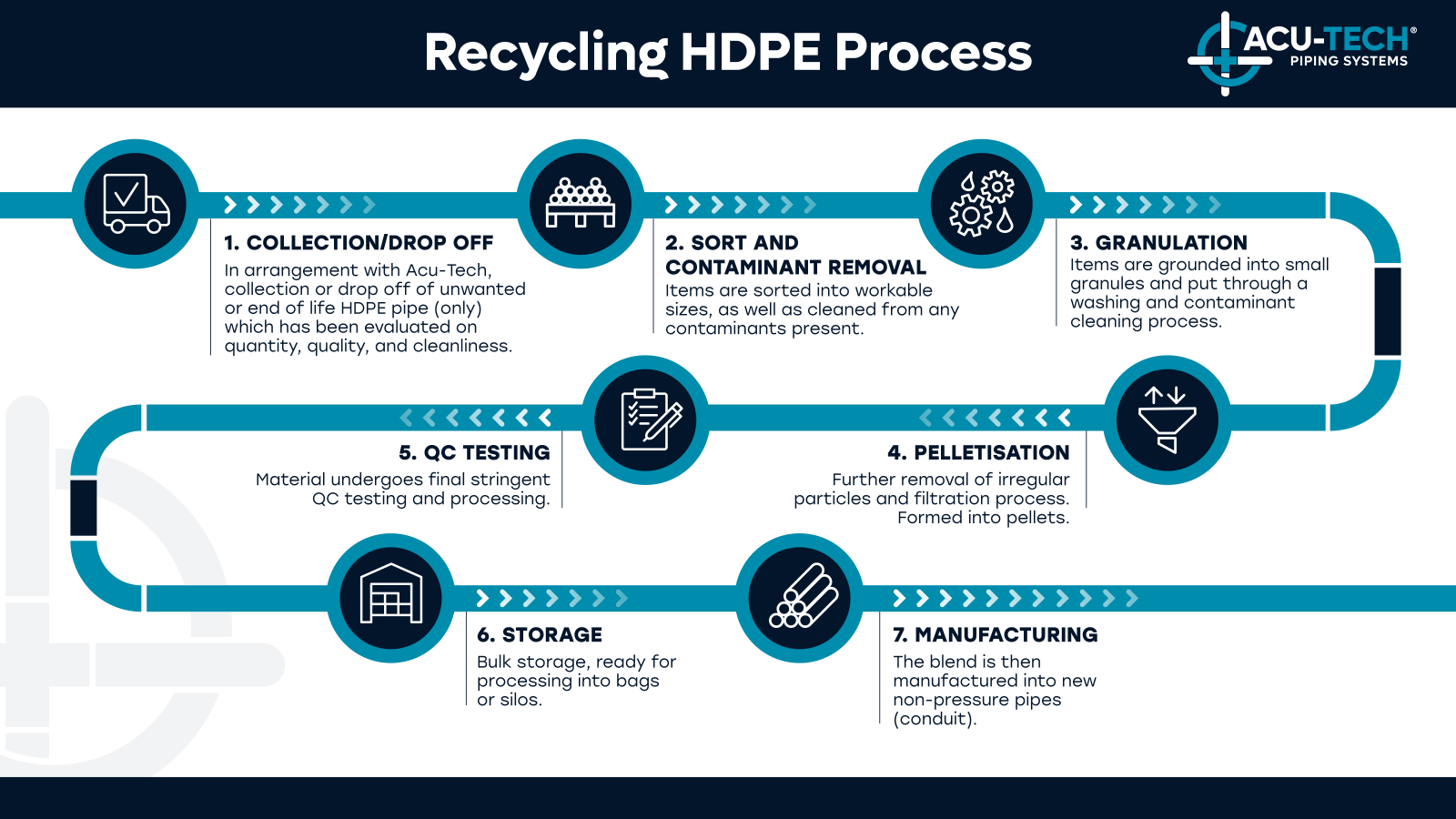

Step-By-Step Process of Recycling HDPE at Acu-Tech:

- Collection/Drop Off: In arrangement with Acu-Tech, collection or drop off unwanted or end of life HDPE pipe (only) which has been evaluated on quantity, quality, and cleanliness.

- Sort and Contaminant Removal: Items are sorted into workable sizes, as well as cleaned from any contaminants present.

- Granulation: Items are grounded into small granules and put through a washing and contaminant cleaning process.

- Palletisation: Further removal of irregular particles and filtration process. Formed into pellets.

- QC Testing: Material undergoes final stringent QC testing and processing.

- Storage: Bulk storage, ready for processing into bags or silos.

- Manufacturing: The blend is then manufactured into new non-pressurised pipes (conduit).

Why do we only accept HDPE?

At Acu-Tech Piping Systems, we only accept PE100 HDPE pipe for recycling as accepting another form of piping like PVC or LDPE would create cross contamination, hence making the pipe contaminated and unusable.Why do we only make Non-Pressurised Pipes with our Recycled HDPE?

The pipe that Acu-Tech recycles is only turned into non-pressurised pipe. This is due to the materials being used for pressurised pipe must be consistent, identifiable, and meet set standards as they transfer important utilities (such as gas and drinking water) that affect the wellbeing and health of the community. Because of this, pre- and post- consumer material is excluded in the production of pressurised pipes. However, manufacturers can reuse their own rework material of the same composition to manufacture pressurised pipes.What piping will we accept?

We will accept any PE100 HDPE pipe for recycling based on its quality, quantity, and cleanliness. Any HDPE Pipe can be dropped off at our Perth and Brisbane locations, with prior arrangement with our team.Why should I recycle HDPE Pipe?

We all should recycle HDPE pipe so we can minimise the impact we have on the environment. Recycling HDPE pipe allows us to redirect it from going into landfill by repurposing and reproducing it into new pipes to be used again.Where can you deliver / drop off your HDPE pipes for recycling?

You can drop off/deliver your HDPE pipe for recycling at the following locations:

For more information about recycling HDPE pipe and how we can work together to minimise our impact on the environment, contact us at sales@acu-tech.com.au or talk one of our team members at 1300 270 270.

For further information on the use of recycled material in plastic pipes across Australia, visit the PIPA website.