HDPE Pipes: The Sustainable Alternative to PVC

HDPE pipes are emerging as a leading eco-friendly alternative to traditional PVC. With the Environmental Protection Agency (EPA) reviewing PVC plastic production and the possibility of a ban looming, the construction industry is actively seeking sustainable solutions.

PVC, commonly used for pipes and other materials, has raised significant environmental concerns in recent years. Polyvinyl chloride (PVC), a type of plastic widely utilised in the construction industry for pipes, fittings, and other building materials, has been found to have a negative impact on the environment throughout its lifecycle, from production to disposal.

A study by the European Commission highlighted that PVC production is responsible for releasing toxic chemicals into the environment, including dioxins and phthalates, which pose serious health and ecological risks.

Why HDPE pipes are Superior

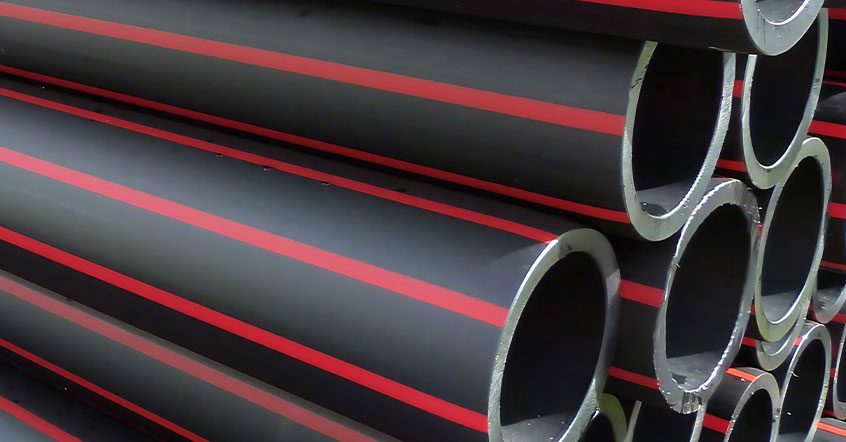

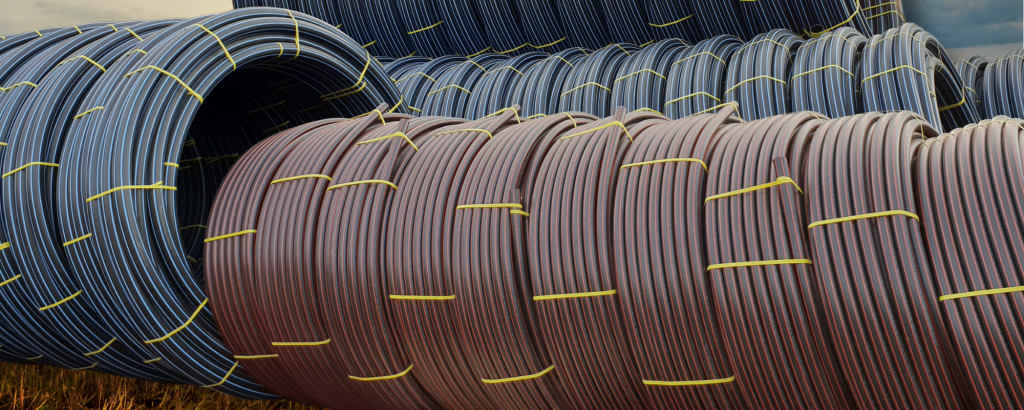

Fortunately, there is a superior alternative to PVC pipes that is not only more environmentally friendly but also offers a range of additional benefits. HDPE, or high-density polyethylene, is a type of plastic that is becoming increasingly popular in the construction industry.

HDPE pipes are made from a plastic that is significantly more durable and resistant to chemicals and corrosion than PVC. This enhanced durability makes them ideal for various applications, including water and gas distribution, sewage systems, and industrial piping. Moreover, HDPE’s robustness and flexibility contribute to its long lifespan and reduced maintenance needs, further highlighting its advantages over traditional PVC pipes.

Durability & longevity of HDPE

One of the main advantages of HDPE pipes is their exceptional durability and longevity. Unlike PVC pipes, which can become brittle and crack over time, HDPE pipes can withstand extreme temperatures and pressure without compromising their structural integrity. This resilience means that HDPE pipes have a much longer lifespan, reducing the need for frequent replacements and repairs. HDPE pipes can last up to 100 years, making them a cost-effective and sustainable choice for any construction project.

Resistance to chemicals & corrosion

HDPE pipes are highly resistant to chemicals and corrosion, making them suitable for use in a wide range of environments. This is particularly important for applications such as sewage systems, where the pipes are constantly exposed to harsh chemicals and substances. Unlike PVC pipes, which can be damaged by certain chemicals, HDPE pipes can withstand a wide range of corrosive substances without deteriorating. This not only extends the lifespan of the pipes but also reduces the risk of leaks and other issues.

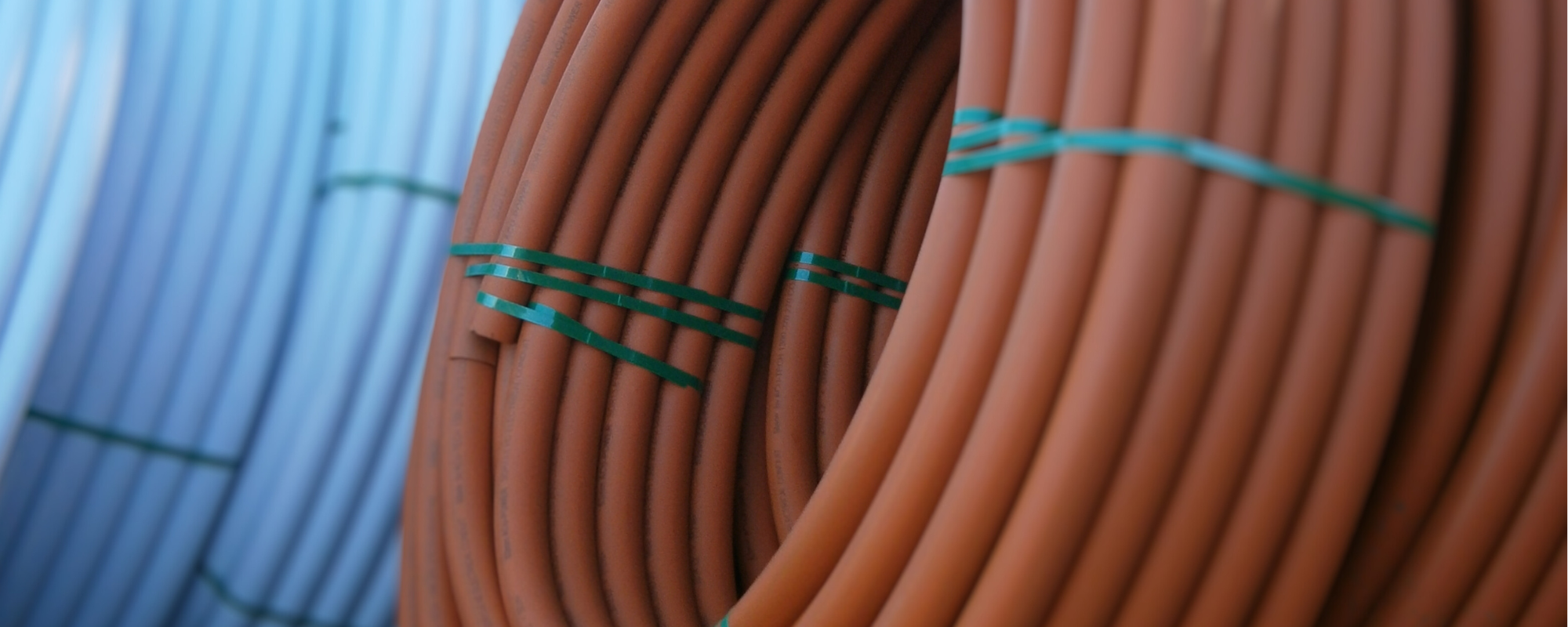

Flexibility & ease of installation

Another benefit of HDPE pipes is their flexibility and ease of installation. Unlike rigid PVC pipes that require precise measurements and fittings, HDPE pipes can be easily bent and molded to fit the specific needs of a project. This flexibility makes HDPE pipes much easier and faster to install, reducing labor costs and minimizing disruptions to the construction process. Additionally, HDPE pipes are lightweight, making them easier to transport and handle on-site.

Environmentally friendly

HDPE pipes are a much more environmentally friendly option than PVC pipes. They are made from a type of plastic that is less harmful to the environment and are fully recyclable. At the end of their lifespan, HDPE pipes can be recycled and used to create new products, reducing the amount of plastic waste that ends up in landfills. This makes HDPE pipes a sustainable choice for any construction project.

Acu-Tech: Your Trusted HDPE Pipe Supplier.

While there are many suppliers of HDPE pipes on the market, Acu-Tech stands out as a leader in the industry. With over 30 years of experience, we’re trusted supplier and fabricator of HDPE pipes and fittings in Australia.

High-quality products

At Acu-Tech, we pride ourselves on providing our customers with the highest quality HDPE pipes and fittings. Our products are manufactured to meet Australian and international standards, ensuring their durability and reliability.

Custom fabrication services

In addition to supplying HDPE pipes and fittings, Acu-Tech also offers custom fabrication services. This means we can create pipes and fittings tailored to the specific needs of your project, saving you time and money on installation.

Extensive range of sizes & options

We understand that every construction project is unique, which is why we offer an extensive range of HDPE pipe sizes and options. This flexibility allows you to choose the best solution for your project, ensuring maximum efficiency and cost-effectiveness.

Acu-Tech has been instrumental in providing and fabricating HDPE pipes for diverse projects across Australia. Our HDPE pipes are a preferred choice in:

-

- Water Distribution Systems: Known for their longevity and resistance to corrosion.

-

- Gas Distribution Systems: Valued for their ability to endure high pressure and extreme temperatures.

-

- Mining Sector: Appreciated for their resilience in challenging environments, capable of withstanding corrosive elements.

Choosing Acu-Tech means choosing quality, reliability, and customised solutions tailored to your specific needs.

Contact us today to get started.