PE100 Poly Pipe Colour Coding Guide: Your Essential HDPE Pipe Reference

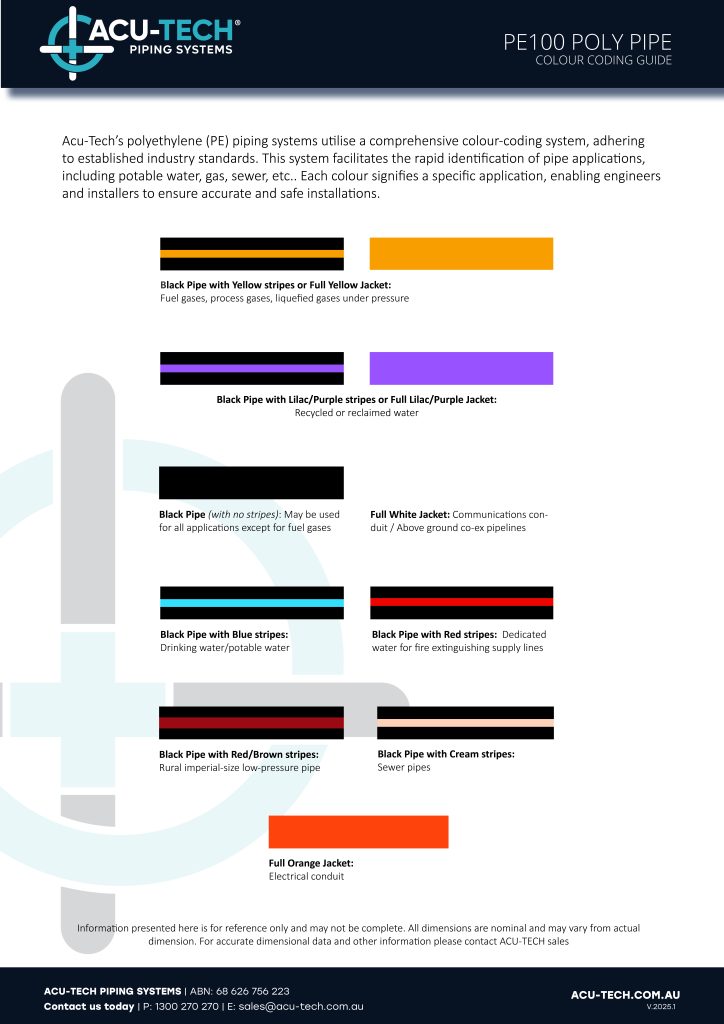

Accurate poly pipe identification is paramount for successful and safe piping systems. Therefore, at Acu-Tech Piping Systems, we’ve developed a comprehensive PE100 Poly Pipe colour coding guide.

This guide provides clear, concise information for professionals working with HDPE pipe and poly pipe systems. Colour coding, crucially, ensures correct installation, maintenance, and safety across numerous applications.

Furthermore, this guide serves as a definitive reference for the colour coding used on PE100 Poly pipe.

PE 100 (Polyethylene 100) is a high-density polyethylene material, celebrated for its strength, durability, and chemical resistance. Consequently, it’s the preferred choice for piping applications, including water supply, gas distribution, and industrial processes. Moreover, our Poly Pipe solutions are engineered to meet the highest industry standards, guaranteeing reliable, long-lasting performance. Indeed, HDPE pipe is recognised for its extended operational life.

Colour coding acts as a vital visual indicator, rapidly identifying the pipe’s intended use and the materials it carries. This allows professionals to prevent installation errors, reduce cross-contamination risks, and streamline maintenance procedures. Specifically, correct colour coding of PE pipe enhances safety.

- Colour: Blue line poly pipe

- Application: Drinking water/Potable Water Supply

- Description: Specifically designated for the transportation of drinking water, ensuring safety and compliance.

- Colour: Red line poly pipe

- Application: Fire extinguishing supply

- Description: Dedicated water for fire extinguishing supply lines

- Colour: Yellow jacket poly pipe or yellow line poly pipe

- Application: Gas Distribution

- Description: Used for natural gas and other gaseous fuels, indicating a potentially hazardous material.

- Colour: Lilac jacket poly pipe or lilac line poly pipe

- Application: Recycled or reclaimed water

- Colour: Black poly pipe

- Application: May be used for all applications except for fuel gases.

- Colour: Full white jacket poly pipe

- Application: Communications conduit, Above ground co-ex pipelines

Firstly, our HDPE pipe and Poly Pipe products use premium-grade materials, ensuring exceptional performance. Secondly, Acu-Tech’s PE 100 solutions withstand harsh conditions and demanding applications. Furthermore, we provide comprehensive technical support and guidance. Finally, we offer a wide range of PE 100 Poly Pipe sizes.