This article appears in the April 2024 issue of Australian Mining, written by Alexandra Eastwood.

Acu-Tech Piping Systems models and manufactures HDPE piping solutions to suit unique mine specifications.

Mineral processing requires robust infrastructure to handle the various fluids, slurries and chemicals involved.

A company that understands this is Acu-Tech Piping Systems , which manufactures high-density polyethylene (HDPE) pipes and fittings for a range of industries.

“Acu-Tech plays a pivotal role in mineral processing by providing reliable and durable piping solutions tailored to the unique needs of the mining industry,” Acu-Tech Piping Systems mining lead Cliff Mataseni told Australian Mining.

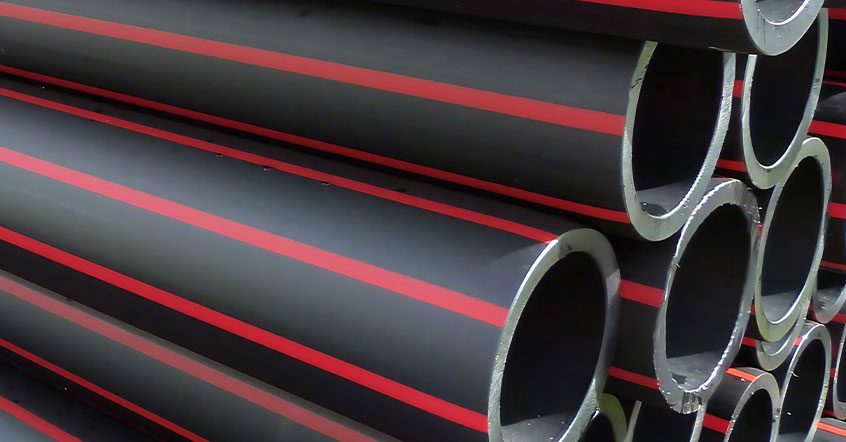

“HDPE pipes have long been the preferred choice for various mining applications due to their unique characteristics and proven performance in rugged terrains, extreme climates, and changing site environments.”

Acu-Tech’s HDPE pipes have been designed for a wide range of mining applications such as slurry and tailings lines, above-ground pipelines, dewatering systems, process piping, leaching processes, remediation projects, and raw water supply, to name a few.

The pipes are designed to withstand aggressive substances commonly encountered in mineral processing plants.

“This durability minimises the risk of pipe and chemical degradation and failure, reducing the likelihood of leaks, spills, and unplanned downtime,” Mataseni said. “Our HDPE pipes are trusted for their flexibility and long-term reliability in demanding environments.”

To complement its HDPE piping solutions, Acu-Tech manufactures and imports a range of fittings that are available in various sizes, configurations and specifications.

“With our experienced operators and fully equipped plastic fabrication workshop, Acu-Tech offers custom fabrication services to meet the specific requirements of mineral processing facilities, optimising the efficiency and reliability of these precise systems,” Mataseni said.

“We fabricate spools, manifolds, and other components from HDPE pipes and sheets to ensure seamless integration into the processing infrastructure.”

Acu-Tech’s HDPE pipes are also made from biodegradable material, boosting durability and environmental outcomes.

“HDPE is a recyclable material with a longer service life, reducing the need for frequent replacements and minimising the environmental impact of mining activities,” Mataseni said.

“The pipes are manufactured through heat-fusion welding, creating seamless and leak-free joints, and eliminating the use of mechanical joints that are prone to leakage. This ensures a reliable and secure pipeline network that limits the risk of environmental contamination and costly repairs.

“HDPE pipes are also significantly lighter than traditional metal pipes, making them easier to handle and install, while their flexibility allows for seamless manoeuvring around obstacles and uneven terrain, reducing the risk of accidents and injuries during installation and maintenance activities.”

Acu-Tech has successfully supplied HDPE piping solutions to numerous mining projects across Australia, one being an iron ore mine in WA.

“The project required the manufacturing and delivery of 270km of bespoke-sized HDPE liner pipe, which was used as a sacrificial corrosion liner within a steel pipeline,” Mataseni said.

“Despite challenges such as deviations in pipe wall thicknesses and a doubling of the initial tendered scope, Acu-Tech delivered the HDPE pipes to the project site through over 900 truck and trailer movements within a compressed timeframe.

“Acu-Tech also manufactured bespoke liners for on-site welding machines and mobilised extra machinery support. The project scope was completed on-time, showcasing Acu-Tech’s commitment to excellence.”

Acu-Tech’s involvement in mineral processing extends beyond HDPE pipe supply and installation.

“We provide comprehensive technical support and expertise to mining operators throughout the project lifecycle, from initial design and material selection to installation and maintenance,” Mataseni said.

“We also offer training programs to educate mining personnel on proper handling, installation, and maintenance practices for HDPE piping systems.

“By empowering operators with the necessary skills and knowledge, we contribute to a safer work environment and mitigate the risk of accidents and incidents.”