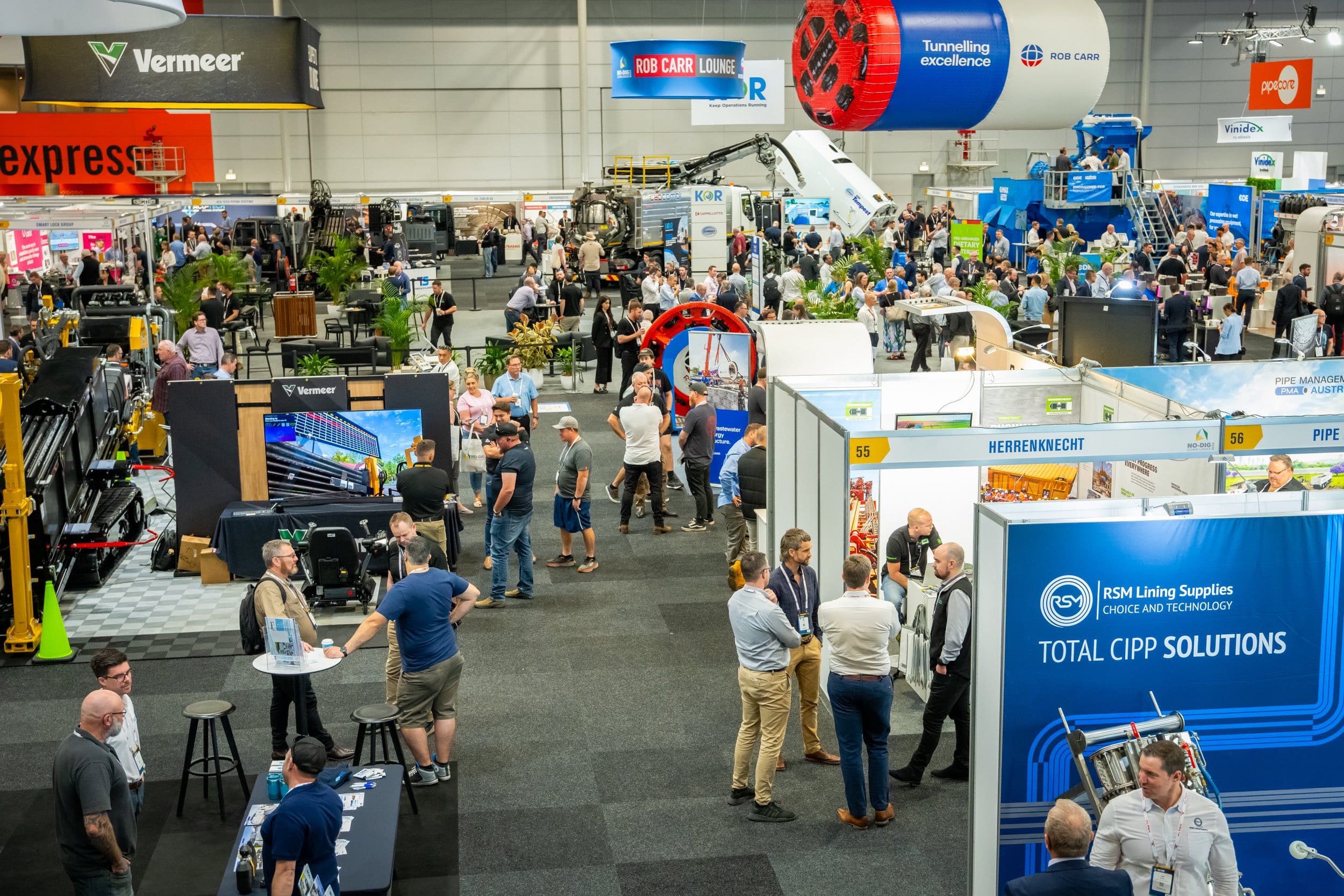

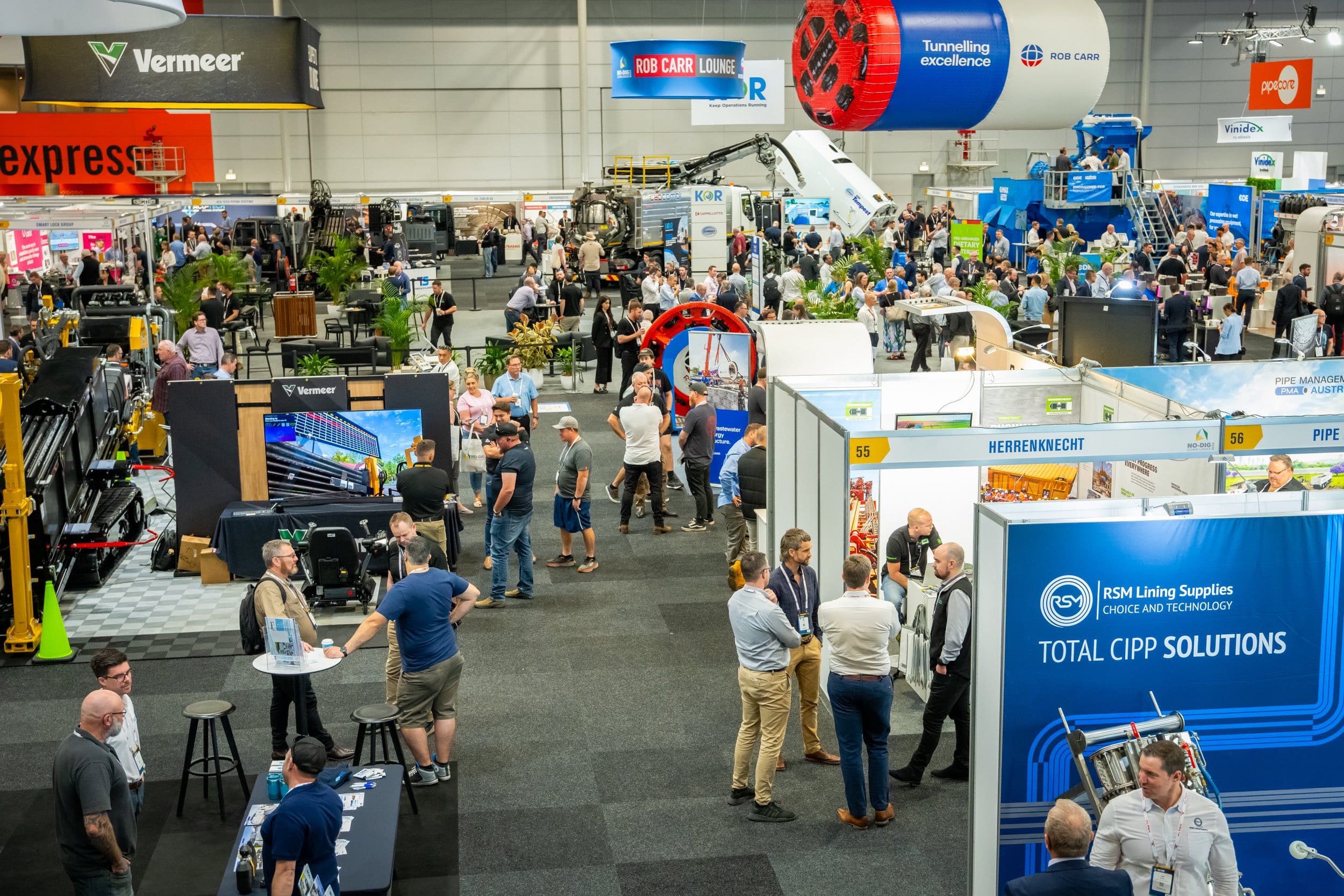

No Dig Down Under 2025.

Acu-Tech team of experts will be exhibiting at the No-Dig Down Under event this September. Come and see us!

We’re proud to share some of our latest developments, highlighting our commitment to excellence in everything we do.

From support for local youth sports to active participation in industry events and expansion of product offerings, here’s a glimpse of what keeps us busy.

Acu-Tech team of experts will be exhibiting at the No-Dig Down Under event this September. Come and see us!

For decades, copper piping has been the standard for plumbing systems. However, modern solutions demand innovation.

Article published in Australian Mining, November 2024 Acu-Tech Piping Systems: Your Trusted Partner for Turnkey Solutions Acu-Tech Piping Systems is proud to be a leading

Waste management is critical to all mining operations. If waste material such as tailings and slurry are not handled safely and responsibly, there can be

Acu-Tech® Piping Systems has been awarded the Supplier of the Year Award by the Civil Contractors Federation Western Australia (CCF WA), recognising our excellence in

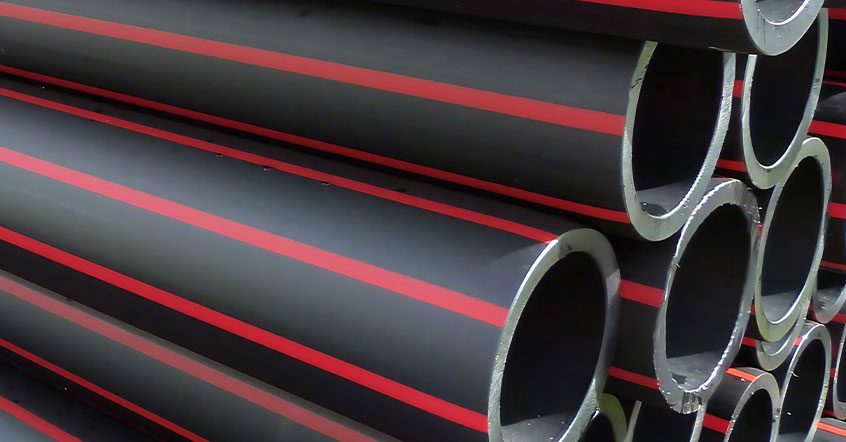

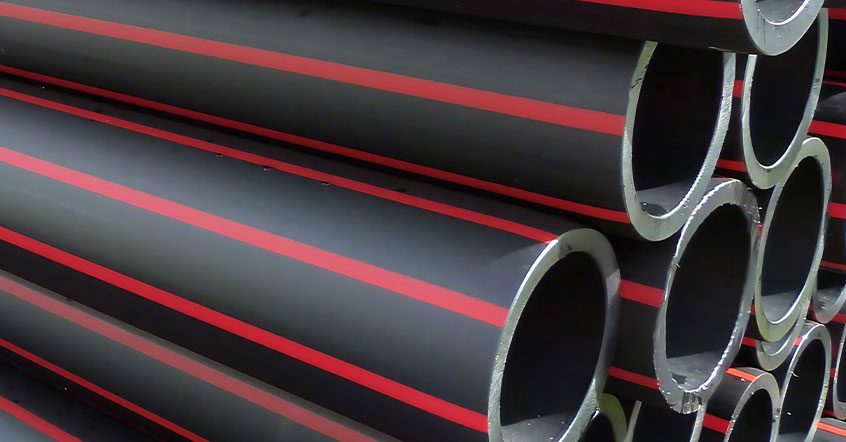

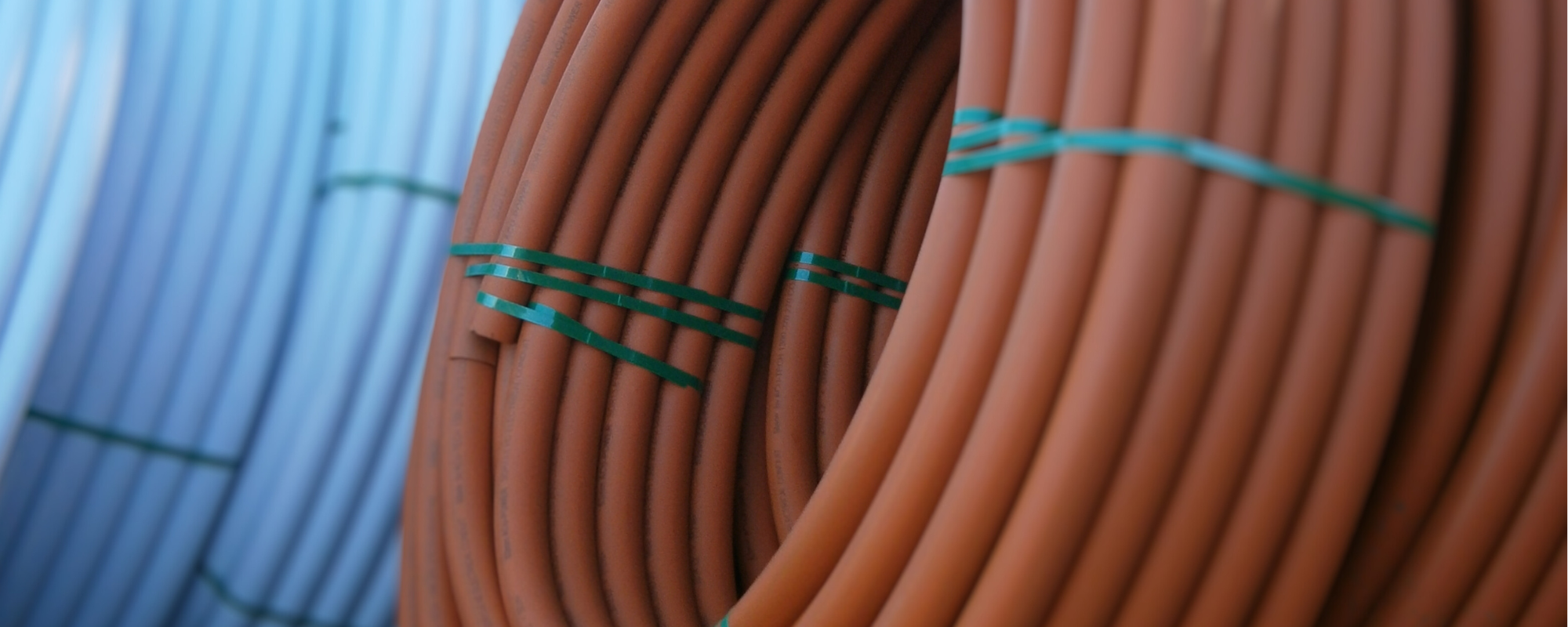

When it comes to piping materials, one option stands out for its durability, versatility, and cost-effectiveness: high-density polyethylene (HDPE) pipe.

HDPEs impressive characteristics, such as toughness, resistance to corrosion, excellent chemical resilience, and lightweight design, make it the preferred choice for cost-effective and reliable piping systems.

HDPE pipes are emerging as a leading eco-friendly alternative to traditional PVC. With the Environmental Protection Agency (EPA) reviewing PVC plastic production and the possibility of a ban looming, the construction industry is actively seeking sustainable solutions.

When it comes to piping materials, one option stands out for its durability, versatility, and cost-effectiveness: high-density polyethylene (HDPE) pipe.

Take a look at this article featured in the April 2024 issue of Australian Mining, written by Alexandra Eastwood.

Acu-Tech Pty Ltd is excited to announce its recent acquisition of JAG Poly. Discover what this expansion means for our clients and the industry.

Acu-Tech is proud to be participating in the MACA Cancer 200 — Ride for Research for the second time this year.