PE pipe markings explained: Reading PE100 HDPE standards

The markings on polyethylene (PE) and HDPE pipes are critical. They are far more than random codes. These printed details confirm pipe quality, safety, and compliance for your project. Each marking provides vital information. This includes the pressure rating, size, material grade, and certification status. Understanding this confirms that every pipe meets essential Australian Standards. The poly pipe colour coding guide will help you decode every marking on your Acu-Tech PE100 pipe and master reading all the PE pipe markings.

Decoding the standard PE pipe markings

Every Acu-Tech PE100 pipe includes clear, easy-to-read markings. These details ensure complete traceability and high compliance. Here is what each part of the code means:

ACU-WATER™ identifies the product trademark

PBS05013150 is the internal product code

S1 shows the production series

DN50 refers to the nominal diameter

PN12.5 indicates the pressure rating

SDR13.6 represents the Standard Dimension Ratio

WMKA 22040 is the WaterMark licence number

PE100 denotes the high-performance material grade

AS/NZS 4130 confirms compliance with Australian and New Zealand Standards

MADE BY ACU-TECH (08) 9238 8000 provides manufacturer details

YYMMDD HHmm records the date and time of production

L5 identifies the production line

<MMM m> shows the metre mark for installation reference. This full set of poly pipe stamps ensures quality assurance.

Material grade, compliance, and PE pipe markings

The PE100 mark denotes the pipe’s high-performance material grade. This is the latest generation of polyethylene pipe. It offers superior strength and a higher minimum required strength (MRS). Therefore, PE100 pipes can handle greater pressures. The material is strong and reliable for many applications, including water, gas, and mining. Always check your PE pipe markings for the PE100 designation.

Sizing, Pressure, and Reading HDPE Pipe Codes

These markings describe the physical specifications. DN refers to the Nominal Diameter. PN indicates the Pressure Nominal or pressure rating. For example, PN12.5 means the pipe can handle 12.5 bar of pressure. SDR stands for the Standard Dimension Ratio. This is the ratio of the pipe’s outside diameter to its minimum wall thickness. A lower SDR number means a thicker wall and a higher pressure rating.

Traceability and manufacturing codes on PE pipe

Every piece of pipe you receive from Acu-Tech carries a unique set of HDPE pipe codes that ensure full traceability back to the factory. This information is critical for quality control and auditing. These poly pipe stamps include the following:

-

Manufacturer Details: Identifies the company that produced the pipe (e.g., MADE BY ACU-TECH).

-

Date and Time of Production (YYMMDD HHmm): Records the exact moment the pipe was made. This helps identify the exact production run or batch. This is important for audits or compliance checks.

-

Internal Product Code (PBS05013150): A proprietary code used by the manufacturer for internal inventory and product history tracking.

-

Production Line Identifier (L5) and Series (S1): These codes show the specific machine and line used. They help keep quality consistent for large orders.

This detailed system ensures that you can verify the pipe’s origin and manufacturing integrity for every project.

Why understanding PE pipe markings is essential

Understanding these PE pipe markings is vital for three key reasons. It ensures your pipe is compliant, traceable, and built for long-term performance

Ensuring compliance and safety on site

The markings verify the pipe’s origin and manufacturing batch. This is critical for regulatory compliance. Installers and project managers gain confidence. They know their systems meet all current Australian regulations. Using marked pipes reduces the risk of project failures or costly delays.

Guaranteeing long-term system performance

The PE pipe markings are your guarantee of quality and longevity. The markings show the PE100 material grade, the Pressure Nominal (PN) rating, and the Standard Dimension Ratio (SDR). These details confirm the pipe can handle long-term stress and environmental factors.

-

Material assurance: The PE100 designation means the pipe meets the highest standard for modern polyethylene. This ensures it resists abrasion, chemical corrosion, and slow crack growth for many years.

-

Pressure management: Checking the PN rating stops the use of pipes in situations they cannot support. This is key for a reliable, long-lasting system.

-

Quality confirmation: The WaterMark and AS/NZS 4130 marks show that the pipe has been tested and certified for Australian conditions by a third party.

By checking these poly pipe stamps, you make sure the system you install today works well for its whole life.

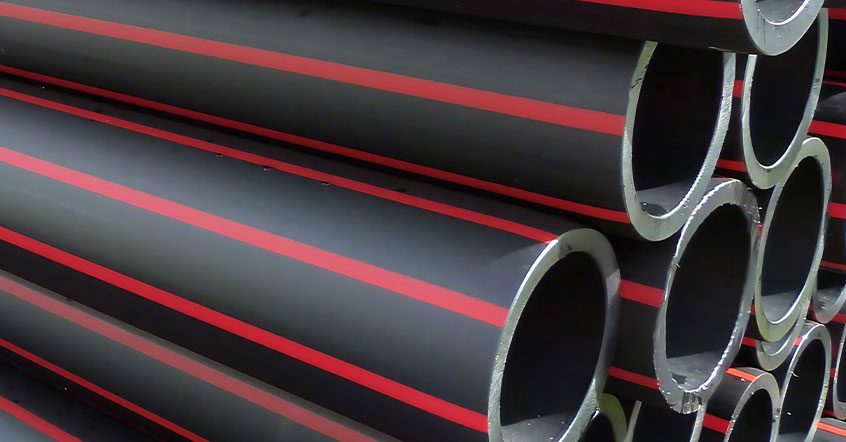

A quick guide to PE pipe colour codes

The colour stripe on a pipe often signals its intended use. This is a crucial visual aid on the worksite. Below a few examples:

-

Blue Stripe: Dedicated to drinking water and potable water applications.

-

Yellow/Orange Stripe: Used for gas pipelines.

-

Red Stripe: Indicates fire mains and related fire protection systems.

-

Purple/Lilac Stripe: For recycled or non-potable water.

For a complete guide, explore the PE100 poly pipe colour coding guide: https://www.acu-tech.com.au/pe100-poly-pipe-colour-coding-guide/

Build your project with Acu-Tech certified confidence

When you choose Acu-Tech, you choose products backed by precision, compliance, and full traceability. Every pipe is printed with clear product information. This ensures consistent quality and certified confidence across all projects.

Contact our team today to discuss your next project.

Explore our PE100 HDPE pipe range to see how Acu-Tech upholds industry-leading Australian standards, backed by clear HDPE pipe codes.

Rated 4.8 / 5 based on 24 reviews