HDPE Pipes: The Sustainable Alternative to PVC

HDPE pipes are emerging as a leading eco-friendly alternative to traditional PVC. The Environmental Protection Agency (EPA) is looking at PVC plastic production. A ban may happen soon. Because of this, the construction industry is searching for sustainable solutions.

PVC, commonly used for pipes and other materials, has raised significant environmental concerns in recent years. Polyvinyl chloride (PVC) is a type of plastic used a lot in construction. It is found in pipes, fittings, and other building materials. However, PVC has a negative impact on the environment. This harm occurs from its production to its disposal.

A study by the European Commission showed that making PVC releases harmful chemicals into the environment. These include dioxins and phthalates, which can harm health and nature.

Why HDPE pipes are superior

Luckily, there is a better option than PVC pipes. This option is more eco-friendly and has many extra benefits. HDPE, or high-density polyethylene, is a type of plastic that is becoming increasingly popular in the construction industry.

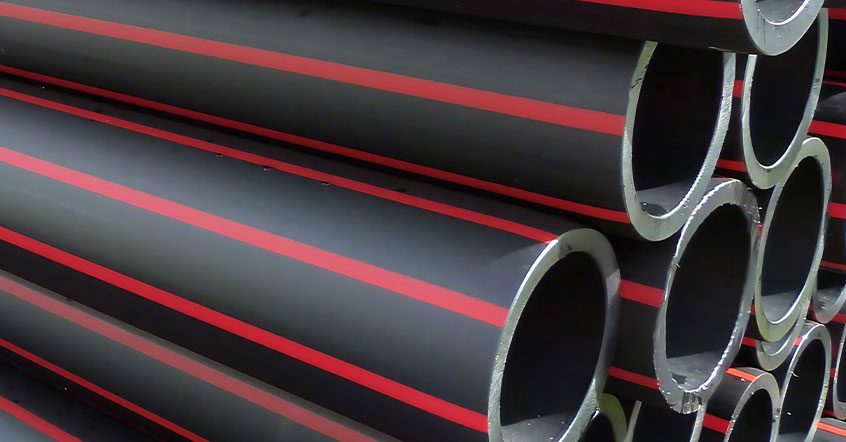

HDPE pipes are made from a strong plastic. This plastic is more durable and resistant to chemicals and corrosion than PVC. This enhanced durability makes them ideal for various applications, including water and gas distribution, sewage systems, and industrial piping. HDPE is strong and flexible. This helps it last a long time and need less maintenance. These qualities show why it is better than traditional PVC pipes.

Durability & longevity of HDPE pipe

HDPE pipes offer superior durability and a significantly longer lifespan compared to traditional PVC. Unlike PVC, which can get brittle and crack over time, HDPE stays strong and lasts for over 100 years. This robust material is highly resistant to impact, fatigue, and pressure surges, making it ideal for demanding applications. Its molecular structure stops micro-cracks from forming. This ensures reliable performance in many conditions, from extreme heat to freezing temperatures.

Resistance to chemicals & corrosion

A critical advantage of HDPE pipes is their exceptional chemical resistance. They are inactive and do not react with or corrode from many chemicals. This includes many acids, bases, and salts. This makes them the preferred choice for industrial applications where the transport of aggressive or corrosive fluids is necessary. The non-corrosive nature of HDPE means it will not release harmful substances into drinking water. This ensures safety and purity, which is a key concern with old PVC pipes.

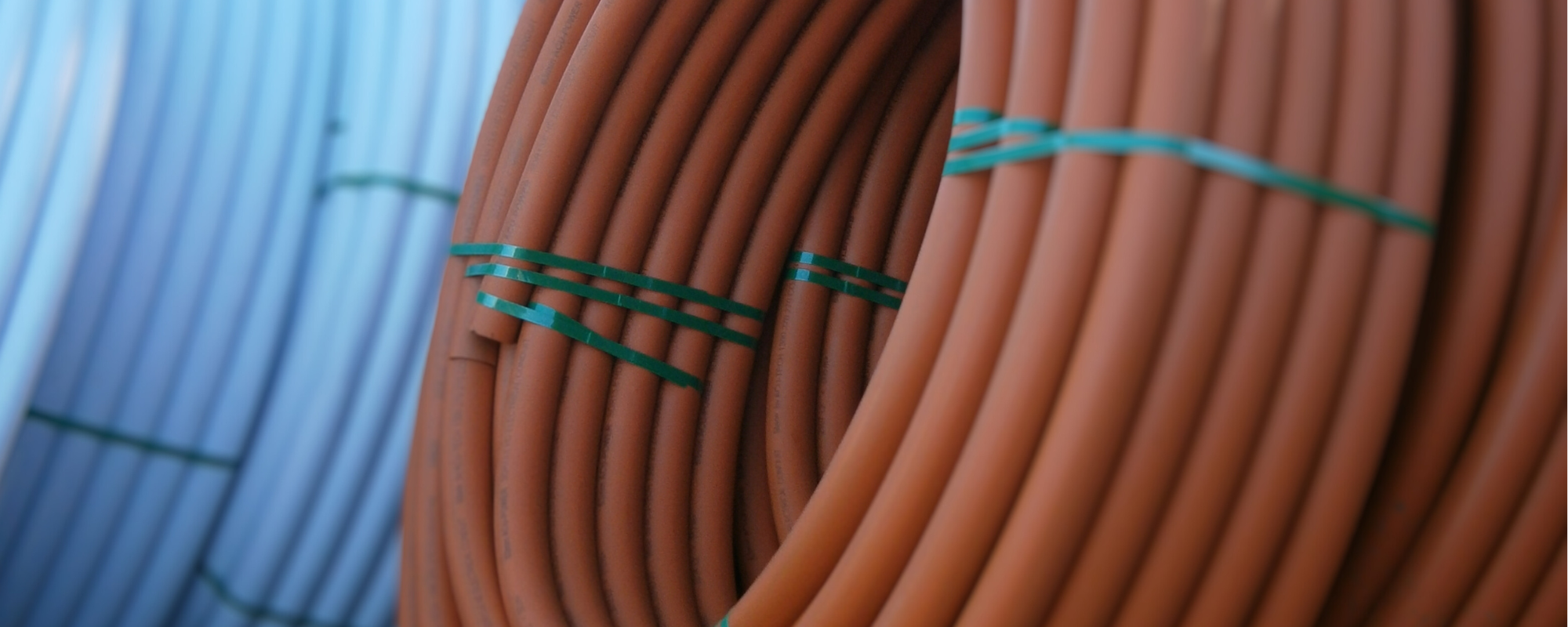

Flexibility & ease of installation

The inherent flexibility of HDPE pipes provides significant installation benefits. Unlike rigid PVC pipes that need many fittings and joints, HDPE can bend to go around obstacles or follow natural shapes. This reduces the need for costly and time-consuming trenching, making it an excellent option for trenchless installation methods. The pipes are connected using a method called heat fusion. This makes a strong, solid pipe system that does not leak. This removes the weak spots at the joints of traditional PVC systems. It ensures a strong and lasting network.

Environmentally friendly

HDPE pipes are a much more environmentally friendly option than PVC pipes. They are made from a type of plastic that is less harmful to the environment and are fully recyclable. At the end of their life, HDPE pipes can be recycled. This helps create new products and reduces plastic waste in landfills. This makes HDPE pipes a sustainable choice for any construction project.

Acu-Tech: Your Trusted HDPE Pipe Supplier.

While there are many suppliers of HDPE pipes on the market, Acu-Tech stands out as a leader in the industry. With over 30 years of experience, we’re a trusted supplier and fabricator of HDPE pipes and fittings in Australia.

High-quality HDPE pipes and fittings

At Acu-Tech, we pride ourselves on providing our customers with the highest quality HDPE pipes and fittings. Our products are manufactured to meet Australian and international standards, ensuring their durability and reliability.

Custom fabrication services

In addition to supplying HDPE pipes and fittings, Acu-Tech also offers custom fabrication services. This means we can create pipes and fittings tailored to the specific needs of your project, saving you time and money on installation.

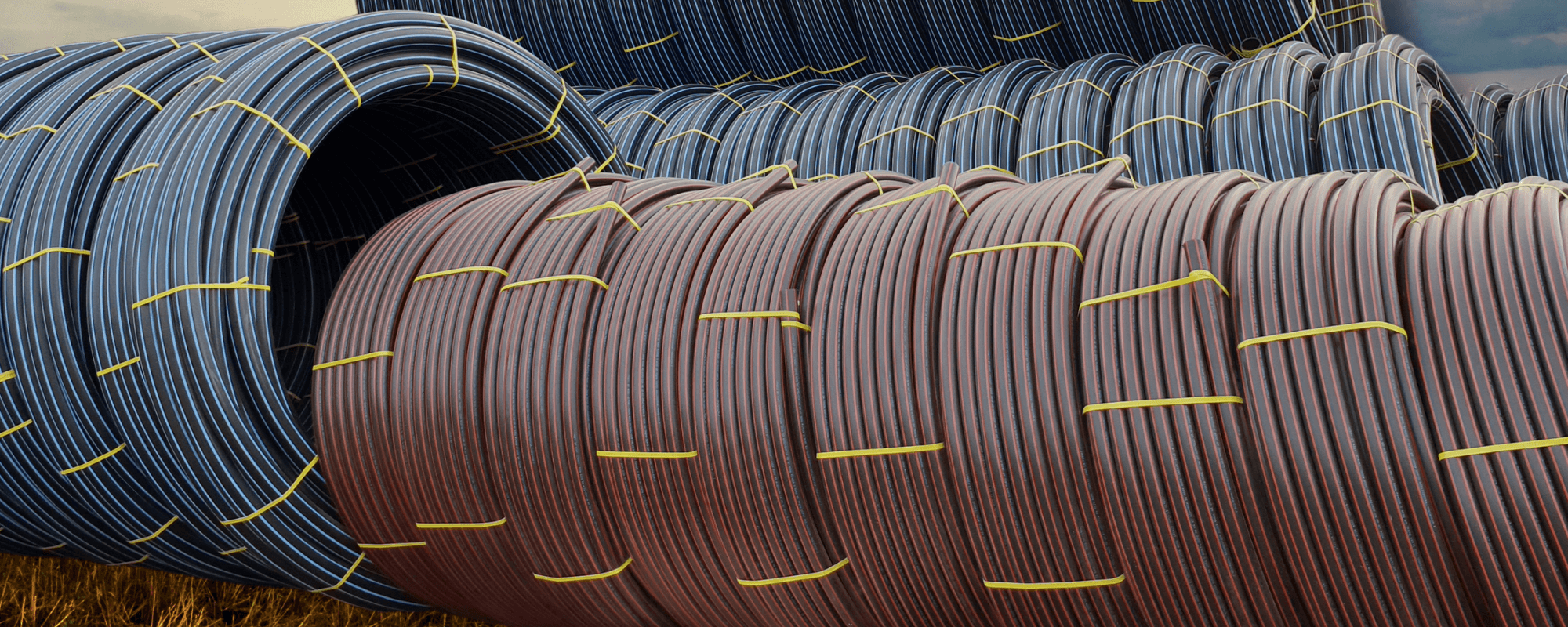

Extensive range of HDPE pipe sizes, fittings & options

We know that every construction project is different. That’s why we provide a wide range of HDPE pipe sizes and options. This flexibility allows you to choose the best solution for your project, ensuring maximum efficiency and cost-effectiveness.

Acu-Tech has been instrumental in providing and fabricating HDPE pipes for diverse projects across Australia. Our HDPE pipes are a preferred choice in:

-

- Water Distribution Systems: Known for their longevity and resistance to corrosion.

-

- Gas Distribution Systems: Valued for their ability to endure high pressure and extreme temperatures.

-

- Mining Sector: Appreciated for their resilience in challenging environments, capable of withstanding corrosive elements.

Choosing Acu-Tech means choosing quality, reliability, and customised solutions tailored to your specific needs.

Contact us today to get started.