PE100 poly pipe colour coding guide: Your essential HDPE pipe reference

The PE100 poly pipe color coding guide is the main standard for identifying how to use HDPE pipe.

PE100 poly pipe is a modern, high-performance material that falls under the broader category of plastic pipe. It is classified as High Density Polyethylene (HDPE). This is the advanced PE100 grade, which has a minimum required strength (MRS) of 10.0 MPa.

The distinct advantage of incorporating PE100 into your piping systems is its inherent corrosion resistance. This ability makes it much more durable and cost-effective than traditional metal pipes in tough environments.

Understanding the colour coding is the first step in ensuring the correct application for this robust, versatile material.

PE100 (Polyethylene 100) is a high-density polyethylene material, celebrated for its strength, durability, and chemical resistance. Consequently, it’s the preferred choice for piping applications, including water supply, gas distribution, and industrial processes. Moreover, our poly pipe solutions are engineered to meet the highest industry standards, guaranteeing reliable, long-lasting performance. Indeed, HDPE pipe is recognised for its extended operational life.

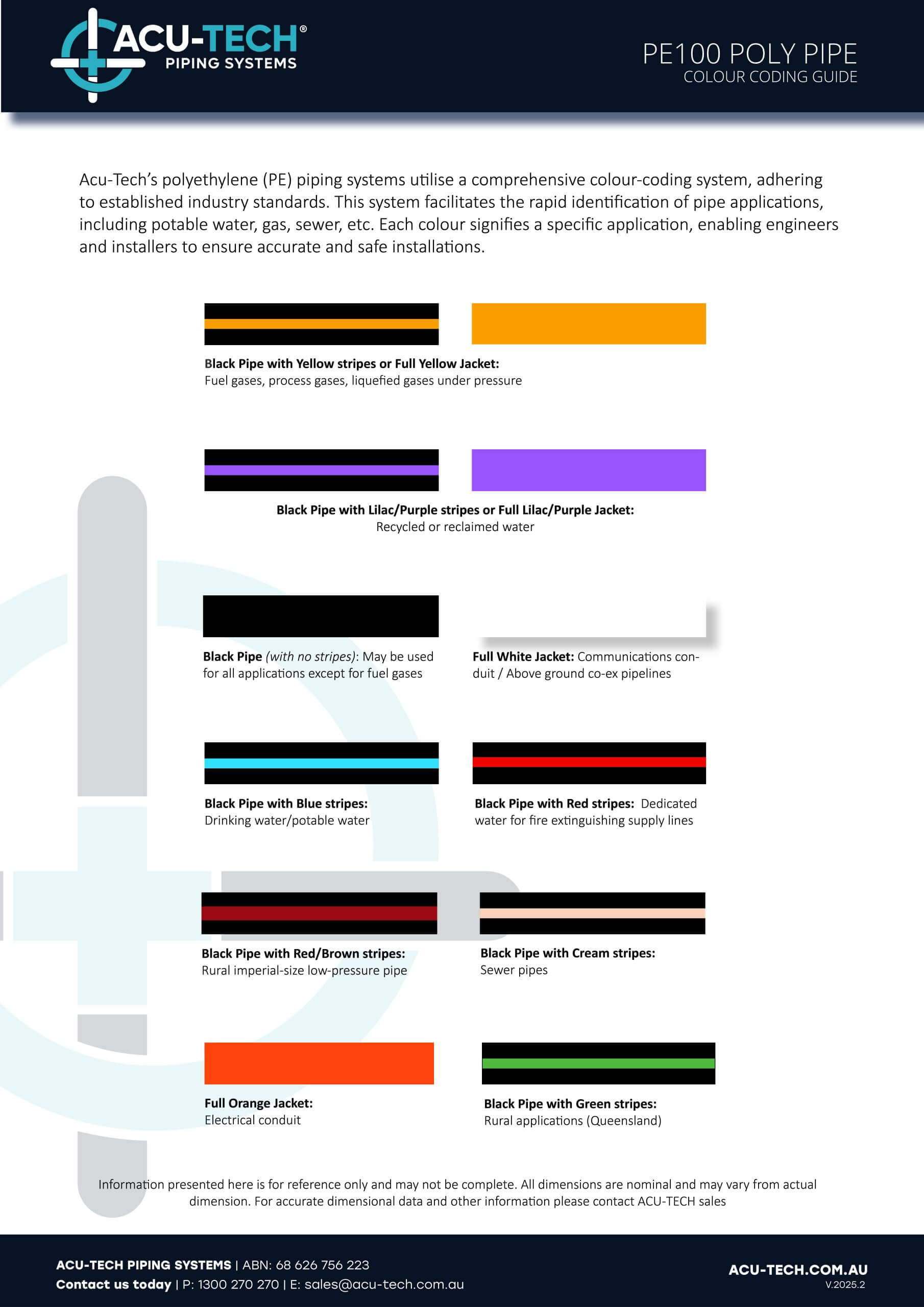

Colour coding acts as a vital visual indicator, rapidly identifying the pipe’s intended use and the materials it carries. This allows professionals to prevent installation errors, reduce cross-contamination risks, and streamline maintenance procedures. Specifically, correct colour coding of PE pipe enhances safety.

- Colour: Blue line poly pipe

- Application: Drinking water/potable water supply

- Description: Specifically designated for the transportation of drinking water, ensuring safety and compliance.

- Colour: Red line poly pipe

- Application: Fire extinguishing supply

- Description: Dedicated water for fire extinguishing supply lines

- Colour: Yellow jacket poly pipe or yellow line poly pipe

- Application: Gas distribution

- Description: Used for natural gas and other gaseous fuels, indicating a potentially hazardous material.

- Colour: Lilac jacket poly pipe or lilac line poly pipe

- Application: Recycled or reclaimed water

- Colour: Black poly pipe

- Application: May be used for all applications except for fuel gases.

- Colour: Full white jacket poly pipe

- Application: Communications conduit, above ground co-ex pipelines

Firstly, our HDPE pipe and poly pipe products use premium-grade materials, ensuring exceptional performance. Secondly, Acu-Tech’s PE100 solutions withstand harsh conditions and demanding applications. Furthermore, we provide comprehensive technical support and guidance. Finally, we offer a wide range of PE100 poly pipe sizes.

The mandated colour-coding bands (e.g., blue for water, yellow for gas) are essential for rapid identification on-site, ensuring the right high density polyethylene pipe is selected for its specific application.

-

Water transport: For pipelines designated for potable water supply, the integrity of the pipe is paramount. PE100 is uniquely suitable for high pressure municipal and industrial water systems. Its molecular structure ensures the joints are completely leak proof and leak free when correctly installed using thermal welding techniques.

-

Non-pressure applications: While much of our focus is on pressure applications, the coding also extends to systems like communication conduits, which require protection from external moisture and physical damage without the need for high-pressure rating.

The long-term performance of these pipes is also favorable in terms of environmental factors. Being chemically inert, PE100 does not leach or react, making it a responsible choice for infrastructure and contributing to project sustainability.

A significant benefit of PE100 is the ease and reliability of its connection process. The material of HDPE pipe allows for strong connections using fusion welding methods. These methods include butt fusion and electrofusion. This creates a solid pipe segment that is even stronger than the pipe itself.

For any project manager considering their next deployment, the efficiency of HDPE pipe installation translates directly into project savings. The pipe is lightweight, and it joins quickly and permanently. This leads to lower labor and equipment costs. HDPE pipe provides a high-quality product. It also offers a cost-effective and reliable system for many uses in modern infrastructure.

For detailed PE100 Poly Pipe colour coding information or to discuss your project, contact Acu-Tech Piping Systems.

Browse our HDPE pipe and Poly Pipe solutions on our website.

Download our colour coding PDF.

To improve your understanding with an overview of High-Density Polyethylene (HDPE) pipe technology on Wikipedia.